| Availability: | |

|---|---|

| Quantity: | |

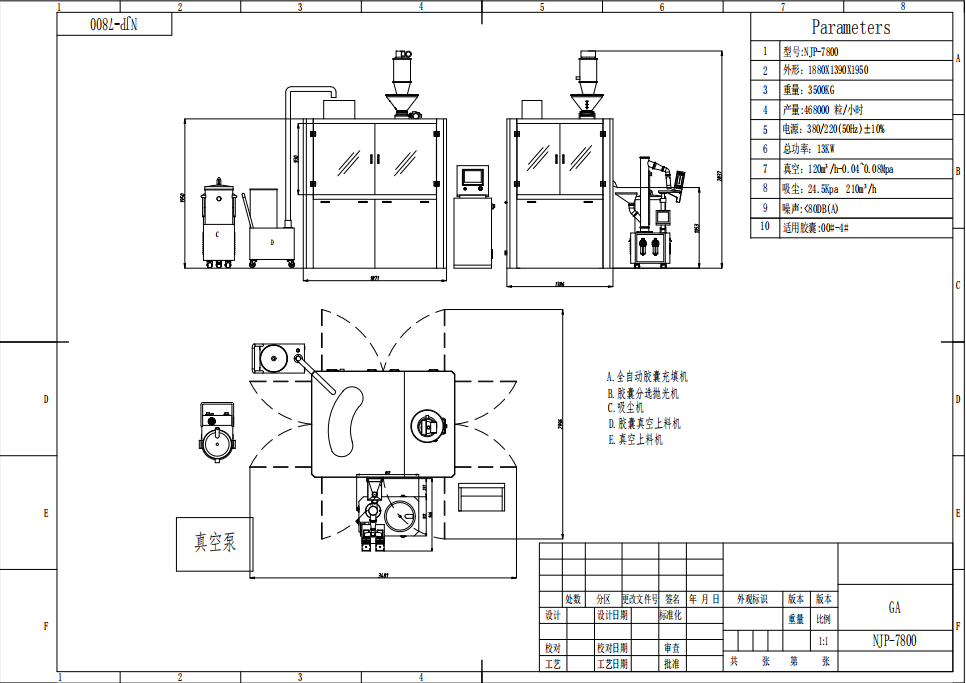

NJP-7800C

Main technical Specifications

Model | NJP-7800C |

Filling capacity | 468000pcs/Hour |

Weight | 3500Kg |

Dimension | 1880×1390×2400mm |

Power supply | 380/220V 50Hz |

Total power | 13KW |

Number of holes | 55holes |

Vacuum | 120m3/h-0.04-0.08Mpa |

Dust collector | 24.5Kpa 210m3/h |

Air compression | Air consumption7m3/h Pressure 7-8Kg |

Water source | 1000L/H 0.3-0.4Mpa |

Operating noise | <75DB(A) |

Filling percentage | Empty capsule 99.9% filled capsule99.8% |

Capsule size | 00,0,1,2,3,4,5#, Safety capsule A-E |

Filling accuracy | Western medicine ±3% Chinese medicine ±4% |

Suitable for | Powder, Granule, Pellet, Tablet. |

New turntableFilling combination

One-piece processing and molding, compact structure and no splicing gap, with good sealing and easy disassembly; the upper and lower modules move independently, and the shaft seal of the fixed bracket adopts a double-lip skeleton dust-proof ring, which achieves no noise, small size, and low load. Small and high precision. The interior of the fully enclosed rotary table is free of maintenance, oil, maintenance and powder for three years. Patent No.: (ZL 2015 2 1021530.0) Modular design is adopted, and the pin-type positioning of the filling holder is used. During production, there is no need to stop the machine to adjust the filling capacity, and it is convenient to replace different filling rods. (Patent No.: ZL 2015 2 1021519.4)

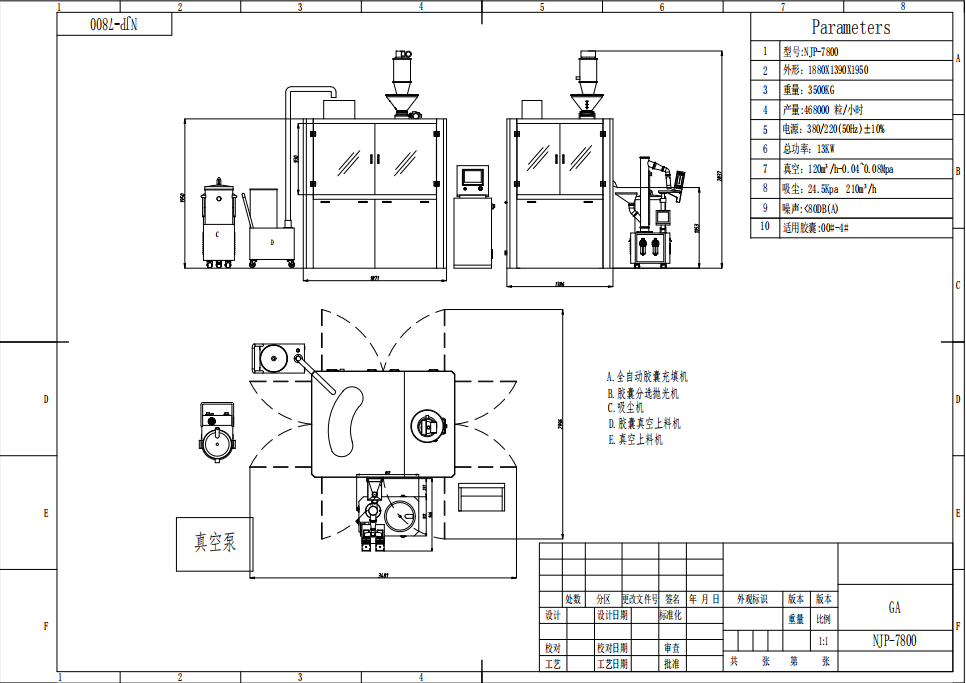

NJP-7800C

Main technical Specifications

Model | NJP-7800C |

Filling capacity | 468000pcs/Hour |

Weight | 3500Kg |

Dimension | 1880×1390×2400mm |

Power supply | 380/220V 50Hz |

Total power | 13KW |

Number of holes | 55holes |

Vacuum | 120m3/h-0.04-0.08Mpa |

Dust collector | 24.5Kpa 210m3/h |

Air compression | Air consumption7m3/h Pressure 7-8Kg |

Water source | 1000L/H 0.3-0.4Mpa |

Operating noise | <75DB(A) |

Filling percentage | Empty capsule 99.9% filled capsule99.8% |

Capsule size | 00,0,1,2,3,4,5#, Safety capsule A-E |

Filling accuracy | Western medicine ±3% Chinese medicine ±4% |

Suitable for | Powder, Granule, Pellet, Tablet. |

New turntableFilling combination

One-piece processing and molding, compact structure and no splicing gap, with good sealing and easy disassembly; the upper and lower modules move independently, and the shaft seal of the fixed bracket adopts a double-lip skeleton dust-proof ring, which achieves no noise, small size, and low load. Small and high precision. The interior of the fully enclosed rotary table is free of maintenance, oil, maintenance and powder for three years. Patent No.: (ZL 2015 2 1021530.0) Modular design is adopted, and the pin-type positioning of the filling holder is used. During production, there is no need to stop the machine to adjust the filling capacity, and it is convenient to replace different filling rods. (Patent No.: ZL 2015 2 1021519.4)

NJP-7800C